Engineer, Test System Designer, Problem Solver

Designing smart mechanical systems for automation, testing, and product validation.

I design and build custom test systems to help clients solve some of their most challenging technical problems, from validating medical devices to ensuring consumer electronic products’ safety. My work bridges engineering disciplines to create functional solutions that make products safer, smarter, and more reliable.

What I do

As a consultant at Exponent, I partner with clients across industries to understand and resolve high-stakes technical challenges. I design and build specialized test platforms that replicate field conditions, simulate failure events, and validate new product designs. These systems integrate motion systems, real-time sensing, embedded controls, and custom software to deliver the precise data my clients need to make critical decisions.

Recent projects span medical device validation, energy storage safety testing, and consumer electronics reliability, each requiring unique instrumentation approaches and creative problem-solving.

How I Work

My work bridges prototyping, instrumentation, and real-world testing with a focus on solving complex engineering challenges in the medical, energy, and consumer electronics domains.

My Core Strengths include:

System Integration: Building complete solutions that coordinate mechanical, electrical, and software components

Custom Instrumentation: Developing specialized rigs for force measurement, thermal monitoring, high-speed imaging, and precision actuation

Precision Prototyping: Leveraging 3D printing, CNC machining, and electronics to deliver functional hardware on tight timelines

Problem Solving Under Constraints: Designing around hazardous test conditions, unknown failure modes and demanding performance requirements

Technical Project Management: Leading technical teams through complex engineering challenges while defining project scope, planning technical resources, and maintaining direct client communication to ensure solutions meet requirements

My Background

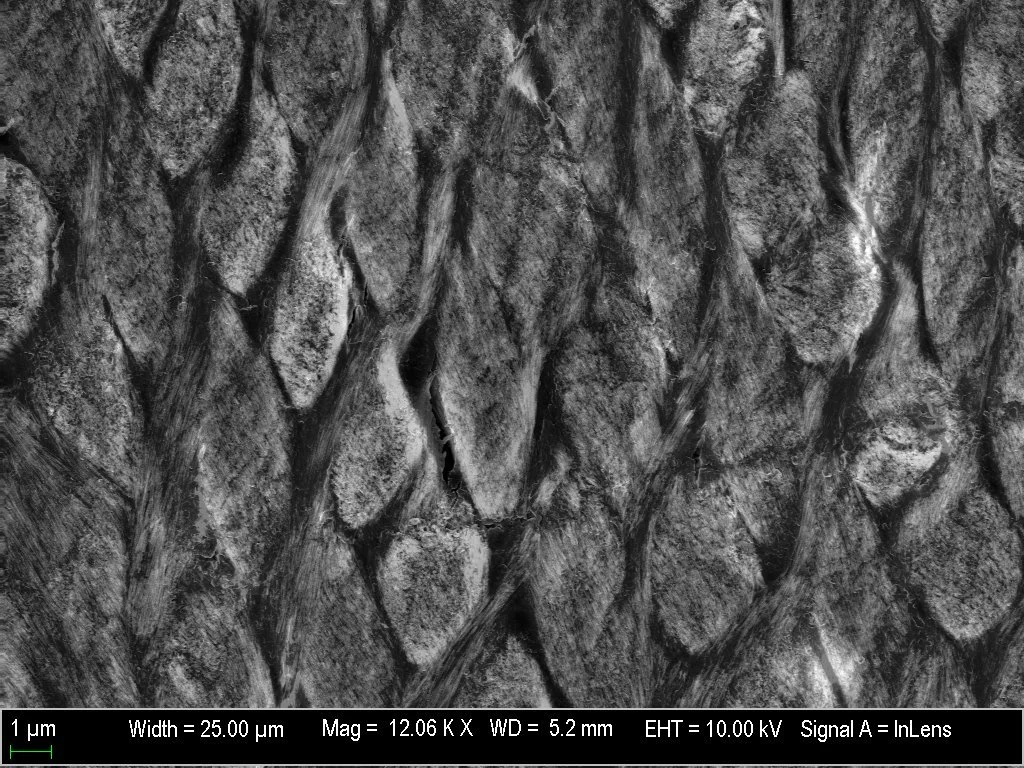

My path to applied engineering began in fundamental research. As a Principal Investigator at the Forsyth Institute, I led NIH-funded research focusing on the molecular origin of the mechanical behavior of mineralized tissues like tooth enamel, work that required developing novel testing methodologies for materials that couldn't be studied with off-the-shelf equipment.

My training at MIT and Imperial College London in nanoscale mechanics, molecular modeling, and electron microscopy gave me a foundation in experimental rigor and data analysis. But what truly shaped my approach was learning to build the tools I needed when they didn't exist, a skill that defines my work today.

What Drives Me

This evolution from asking "why" to asking "how can we solve this?" reflects what motivates me: building functional systems that help teams tackle real-world problems. Whether it’s a large-scale platform for testing cardiac implants ex vivo, an impact platform for lithium-ion safety studies, or a computer-controlled system for precise biologic tissue sampling, I’m motivated by the opportunity to make products safer, smarter, and more human-centered.

I thrive at the intersection of hands-on engineering and creative problem-solving, working across disciplines to build systems that work, and work well.